Orbital welding is a unique process of connecting metal pipes. This technique is great for checking whether pipes are clean and safe. When we discuss high-purity piping, we’re talking about pipes that must be super clean because they convey things like water for drinking or special chemicals to make medicines. At Hongyuan, we are placing the best tools like orbital welding into our hands to see that our pipes meet the highest cleanliness standards. It allows many industries, including food and medicine, to guard their products against contamination of any kind.

Why Orbital Welding Is Ideal for High Purity Piping Systems

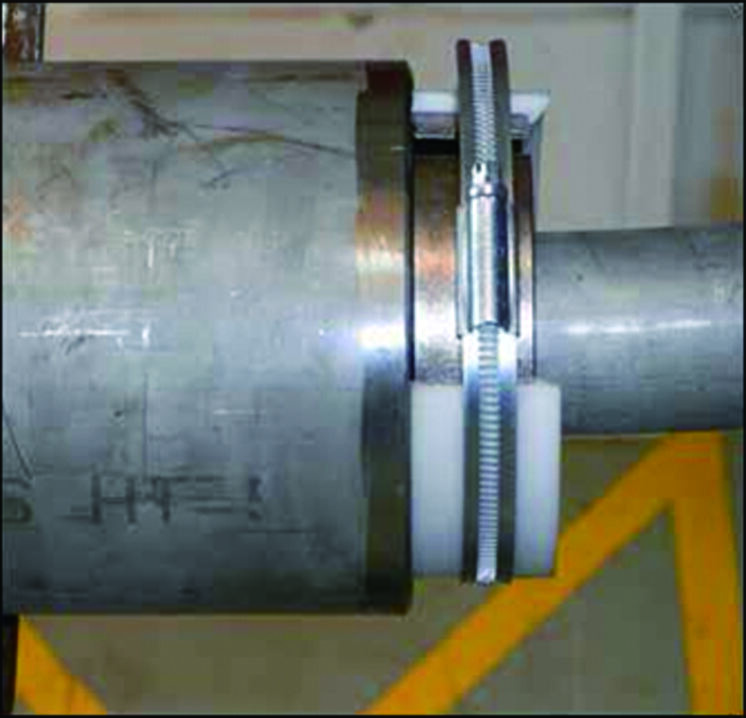

The best way to weld for high purity piping is the orbital weld! One is that it produces a great weld. It’s that the pipes stay together nicely and don’t tip. A leak in a high purity system can lead to major problems, such as contamination, something we always aim to steer clear of. Again, when we're welding by this process, we use machines that rotate around the pipe. This movement is very precise. They work like, say, a robot drawing a perfect circle. That level of accuracy means a cleaner weld. Also, since we’re utilizing machines here, human error is much less likely. This means that every weld can be assumed to be a good one. Another advantage to orbital welding, he said, is that it lessens the dirt getting into the pipe. When we manually weld sometimes dust and dirt will fall in and that is bad for high purity systems. With orbital welding, the process is more controlled which also serves to keep things clean. Clean pipes are a necessity in industries such as pharmaceuticals or food processing. Contaminated material, if there is any, can spoil an entire batch of products. Hongyuan understands how important it is, that’s why we always select an orbital welding for our high purity pipes. The technology is durable and provides the high performance required for these crucial sectors.

Why Is Orbital Welding Perfect for Sanitary Applications?

Hygiene applications must be cleaned specially and stored safely. Orbital welding is ideal for this thanks to strong and cleaner welds. The term sanitary applications conjures up images of hospitals, food factories and labs. These are places where cleanliness is important. When we perform orbital welding, we ensure that the heat which is applied to fuse the pipes spreads homogeneously. This consistent heat works to kill bacteria and other germs that may otherwise be dangerous. We know at Hongyuan that busting big wads of germs in sanitary applications. Which is why we believe in orbital welding. It's also how we meet health-organization guidelines. A factory that fails to comply with these rules can suffer serious consequences. Also, the construction of the pipes can serve to assist with hygiene. The orbital welding machine allows us to make smooth joints free of bumps or gaps. This smoothness makes there less place for dirt or germs to hide. Bumps The bumps on some pipes also tend to collect bacteria, and may make it harder to clean. So in orbital welding, we want to size everything as smooth as we can. Now of course the speed of orbital welding is a huge advantage as well. It lets us get projects done fast and not have to worry about being messy. This speed can really help companies that have been juggling busy schedules and tight deadlines while making sure their systems are safe. After all, orbital welding for sanitary is the smart choice. It keeps you clean, safe and efficient. At Hongyuan, we are committed to the optimal way of investment for our clients important work.

Where to Discover the Finest Orbital Welding Providers for Wholesale Consumers

If your want to buy best orbital welding service. Hongyuan is a good selection. Hongyuan is expert at precision welding, especially in high purity systems. But those are where, exactly? First, start by checking online. Several of them, like Hongyuan, have websites that explain what they do and how they might help you. You can view images of their work, and read about their experience. Checking other customers' reviews is also critical. Some reviews help you determine if a company is trustworthy. Another smart idea is to request for referral. Speak with people in your industry who have had to use orbital welding services before. They can tell of their experiences and point out good companies.

Ask Questions When You Get in Touch with Hongyuan

When you want to get in touch with Hongyuan there are some things that you should ask. You are interested in how they shoot, what it is like and what gear they are using. Good communication is key. Hongyuan has very good workers specialize in orbital welding, so they are one of the best choices. They’re equipped with the very latest technology to make sure every weld is spot-on. This is critical in high purity pipe system where all it takes is one small mistake and something becomes contaminated. You should also enquire about what they charge. Quality is one thing, but finding a service that’s in line with your budget is also important. Hongyuan frequently gives you a good deal without compromising the quality. Finally, consider the location. Wholesale buyer If you are a wholesale buyer, find out if the company is near your business. This helps with moving materials and holding meetings. Finally, the best orbital welding services are researched and discovered by asking the right questions. Hongyuan is the superior choice for high purity welding services.

Clean Constructions with Orbital Welding and Guidelines to Achieve Clean Results

Orbital welding system is a unique welding process, it helps to maintain high purity systems clean. There is a high importance on preventing contamination, such as in food, beverages or pharmaceuticals. Because if dirt, bacteria or other unwanted elements of life make it into the pipes, contamination can occur. That's where orbital welding really excels. Orbital welding is a safer choice because it produces clean, high-quality welds in general. The welding process is conducted in a controlled environment so there’s less chance for dirt or dust to get in.

If you are welding in the old way, there’s more chance of getting impurities. For instance, when welding takes place, the sparks and heat may draw in dust and other particles. But with orbital welding, the machine does the heavy lifting. The welder does not need to be so close to the pipe, which tends to keep the area cleaner. Hongyuan uses quality materials that perform in high-purity applications. Orbital welding apparatus is likewise constructed to reduce the possibility of contamination. The machines produce even heat and pressure, so the welds are uniform and sturdy.

The other factor is that there is the possibility of automating orbit welding. That means the process is automated, rather than done by hand. Automation enables us to make every weld the same, and that’s good for quality control. With the help of technology from Hongyuan, you can rely on it to do your welding job properly every time to minimize the potential for leaks or weak spots that might cause contamination. In conclusion, orbital welding is a good option for high purity systems as it forms clean and strong welds in a sanitized atmosphere. This allows us to keep product safe and free of outside contamination, becoming a gold standard for the industry.

What Are the Top Advantages of Orbital Welding for Food and Beverage?

There are several advantages to using orbital welding for food and beverage applications. First, it is highly conducive to having very strong welds. For companies such as Hongyuan, this is an urgent matter. Strong welds also mean that the Pressure piping components are less likely to leak. Where there’s food, leaks can cause spoilage or contamination, and that's bad for business. Engaging orbital welding, companies can be assured in the reliability and safety of their equipment.

A second advantage is that orbital welding results in sanitary welds. Cleanliness is of the utmost concern in food and beverage. Dirt or bacteria could spoil food and drink. Orbital welding is performed in a configuration with minimum possibility of contamination. Orbital welding equipment is built to keep the work area clear and free from contaminants. This is to ensure that the finished products are safe to be used by consumers.

Moreover, orbital welding is efficient. Time is money in a bustling food or beverage business. The faster the weld process is finished, the sooner production can go on. Hongyuan’s automated orbital welding is time saving because machines are able to work fast and consistent. So there is less downtime and more productivity. What’s more, because the process is so predictable, companies can spend less time looking for mistakes or correcting them.

Cost-effectiveness is another key benefit. Although the setup cost of orbital welding is higher, it offers substantial long-term advantages. Companies save on repairs and maintenance because the welds are strong and long-lasting. That being said, over the long-haul orbital welding can actually save money. In conclusion, the main advantages of orbital welding for food and beverage applications are solid and hygienic welds as well as time and money. If your business depends upon safety and quality you’ll find that Hongyuan’s orbital welding services are a perfect fit.

Table of Contents

- Why Orbital Welding Is Ideal for High Purity Piping Systems

- Why Is Orbital Welding Perfect for Sanitary Applications?

- Where to Discover the Finest Orbital Welding Providers for Wholesale Consumers

- Ask Questions When You Get in Touch with Hongyuan

- Clean Constructions with Orbital Welding and Guidelines to Achieve Clean Results

- What Are the Top Advantages of Orbital Welding for Food and Beverage?